Instant, Reliable Quality Control

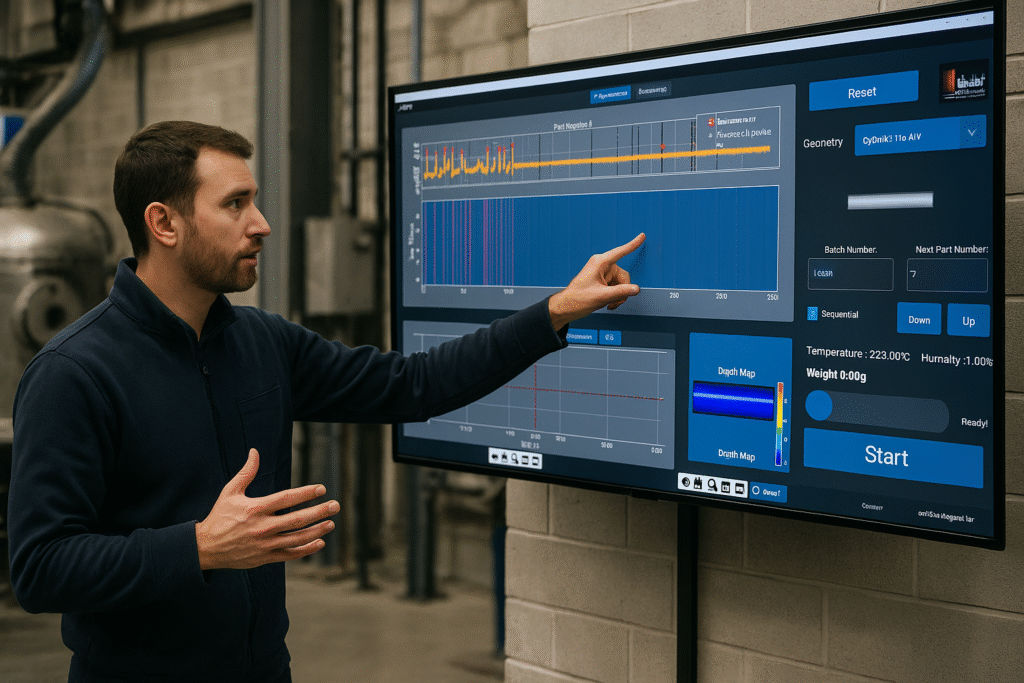

VibroTrace monitors your process in real time using vibrational analysis and AI. It delivers instant, trustworthy decisions on stiffness, integrity, and geometry.

Plug into manufacturing lines and get clear pass/fail decisions with full traceability.

Results in seconds with pass/fail and trends

Works on complex geometries and AM parts

Clear, traceable insights for automation

What We Offer

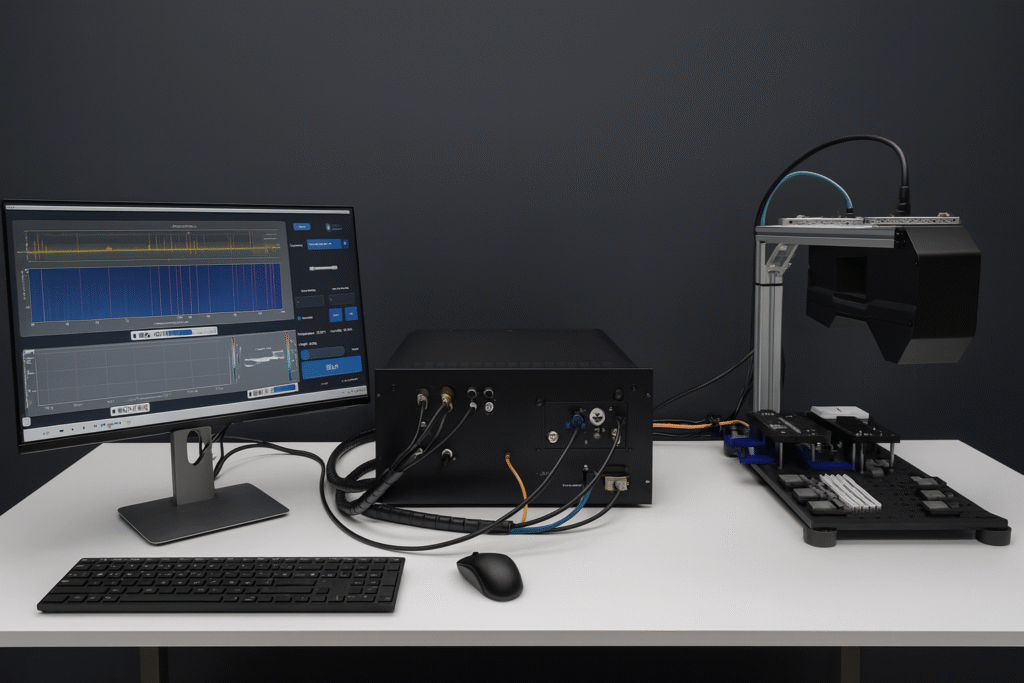

VibroTrace helps manufacturers ensure product reliability by offering fast non-destructive testing and real-time quality insights. By combining vibrational analysis, AI-driven data interpretation, and 3D geometry inspection, we provide automated quality control within seconds.

Fast Precision Testing

VibroTrace combines vibrational testing with vision technology to deliver fast quality inspection for complex-shaped parts. Within seconds, it assesses material stiffness, part integrity, and 3D geometry.

Automated Data Analysis and Insights

VibroTrace utilizes advanced statistics, machine learning and AI to analyze testing results by a single click. Through a digital twin, it provides actionable insights to enhance your manufacturing process and ensure consistent product quality.

Innovative Solutions for Diverse Industrial Applications

VibroTrace integrates cutting-edge technologies to deliver precision quality control for a wide range of materials including metals, polymers, and composites, and across multiple manufacturing methods including additive manufacturing (AM) and injection molding, ensuring consistency and high performance throughout production.

Request DemoWhy Choose VibroTrace?

Smart. Fast. Reliable.

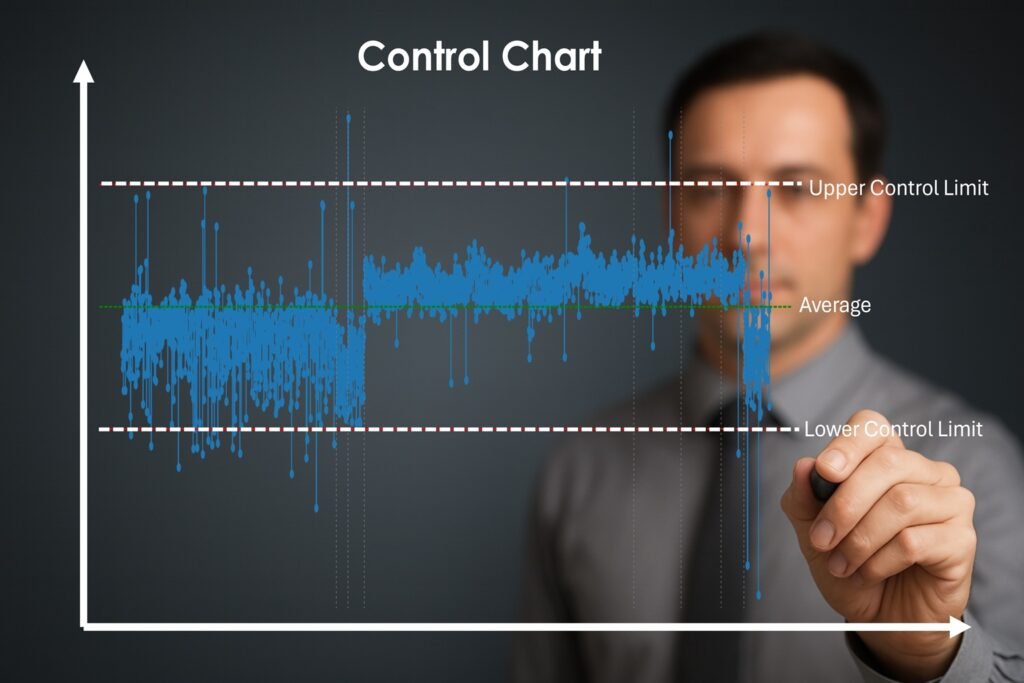

Quality Control 4.0

Real-time, AI-driven inspection and traceability across your production line.

Fast, Simple & User Friendly

One-click testing, clear pass/fail decisions, and minimal operator training.

Process Monitoring

Detect drift early, track stability, and improve long-term process capability.